Our Factory FOTMA is the professional manufacturer of the railway wheel, forged wheel, cast iron wheel, train wheel, steel crane wheel set which with more than 15 years designing and producing experience. With our own forging workshop, machining workshop, heat treatment workshop, we can provide all kind of wheels with different materials, such as ZG430640 cast steel, 60#, 65 #, 65Mn, 42CrMoA or according to your demands. We always insist on attentively manufacturing, keeping on improving and elaborately serving to make customers satisfied. And many good assessment had been received.  Our Products We produce most type of wheel for railway usage, we can supply most of international standard, such as AAR M-208, AAR M-107, UIC 812-3, BS 5892-3, JIS E5402-2, IRS R34, TB/T 2817.

Our Products We produce most type of wheel for railway usage, we can supply most of international standard, such as AAR M-208, AAR M-107, UIC 812-3, BS 5892-3, JIS E5402-2, IRS R34, TB/T 2817.

The Application: Railway vehicles, locomotive, freight wagon, coach, ore car and so on.

Type: Casting Wheels, Forging Wheels.

1) Material: 60#, 65 #, 65Mn, 42CrMoA

2) Heat treatment: Hardening and tempering, high frequency quenching, carburizing quenching and so on

3) Trand surface and rim quench hardness: HRC45-55

4) Trand surface and rim quench depth: 15-18mm

5) processing wheel diameter: Φ 300-2000mm

6)Precise measurement and surface finishes are available

7)Inspection: All items are checked and tested thoroughly during every working procedure and after the product is finally manufactured to ensure that best quality product goes out in the market.

8)good quality with reasonable price, timely delivery and great customer service

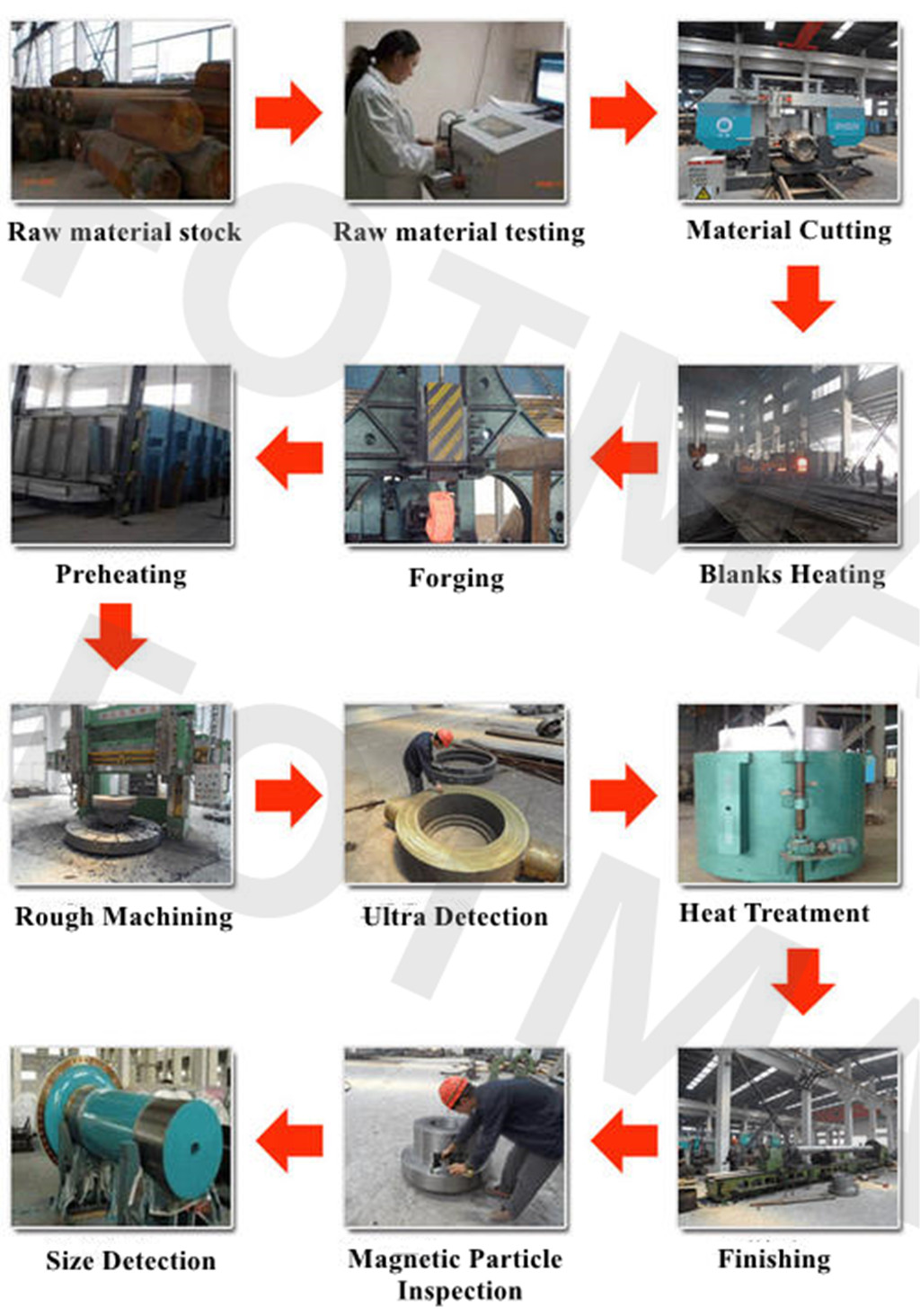

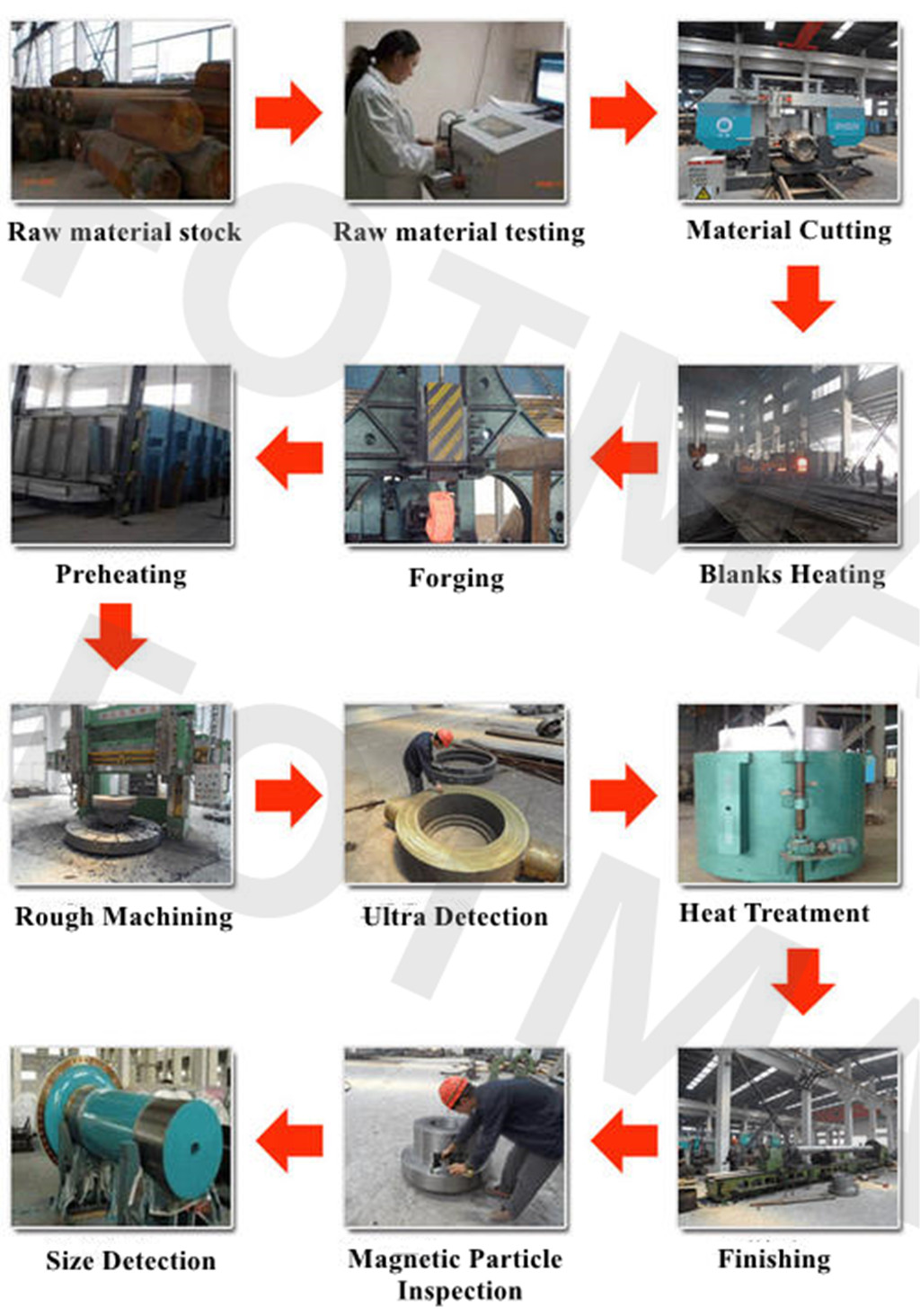

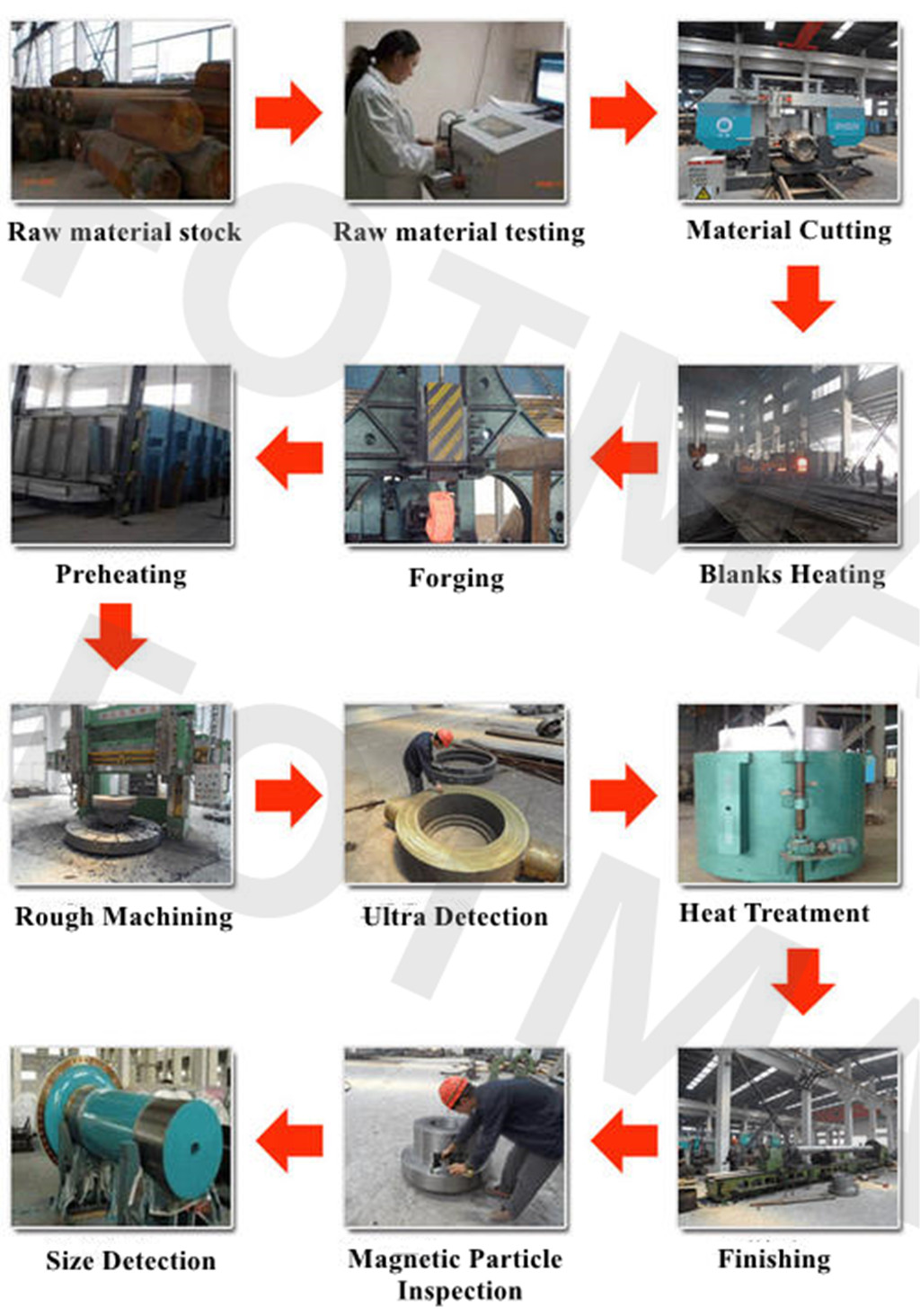

Control & Service

(1) Machinery properties and Chemical components testing after raw casting

(2) Hardness checking after heat treatment

(3) Dimensions testing after machining

(4) Quality control checks though all the following flow:

Drawings→ mould making →raw casting → sandblasting →rough machining or finish machining →surface treatment →product check→ packing →delivery

Service

(1) OEM and custom-made service.

(2) Full machining, primer painting, and surface treatment.

(3) Full material testing process.

(4) Quality control

Packing & Delivery

Packing & Delivery

Contact Us Cherry Zhao

Contact Us Cherry Zhao

Email: bunny@fotma.com

Cell & WhatsApp & WeChat: +86-13995656368